Product & Supply Chain Compliance Software for Importers and Retailers

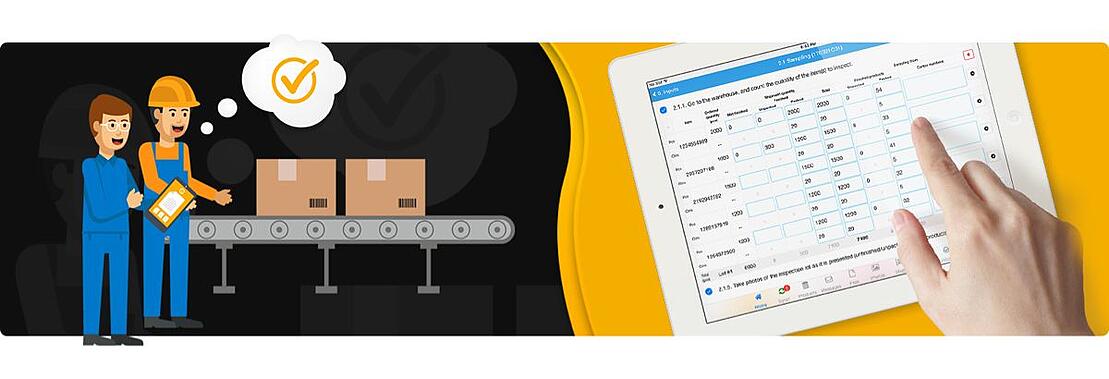

Quality inspection software is an app-based solution to facilitate QC inspections commonly used on a smartphone or tablet that replaces spreadsheets and paper. It allows quality inspectors to schedule QC jobs, input product & supplier information, estimate workloads, select checkpoints to follow, send automated emails to suppliers, and share results with management in real time.

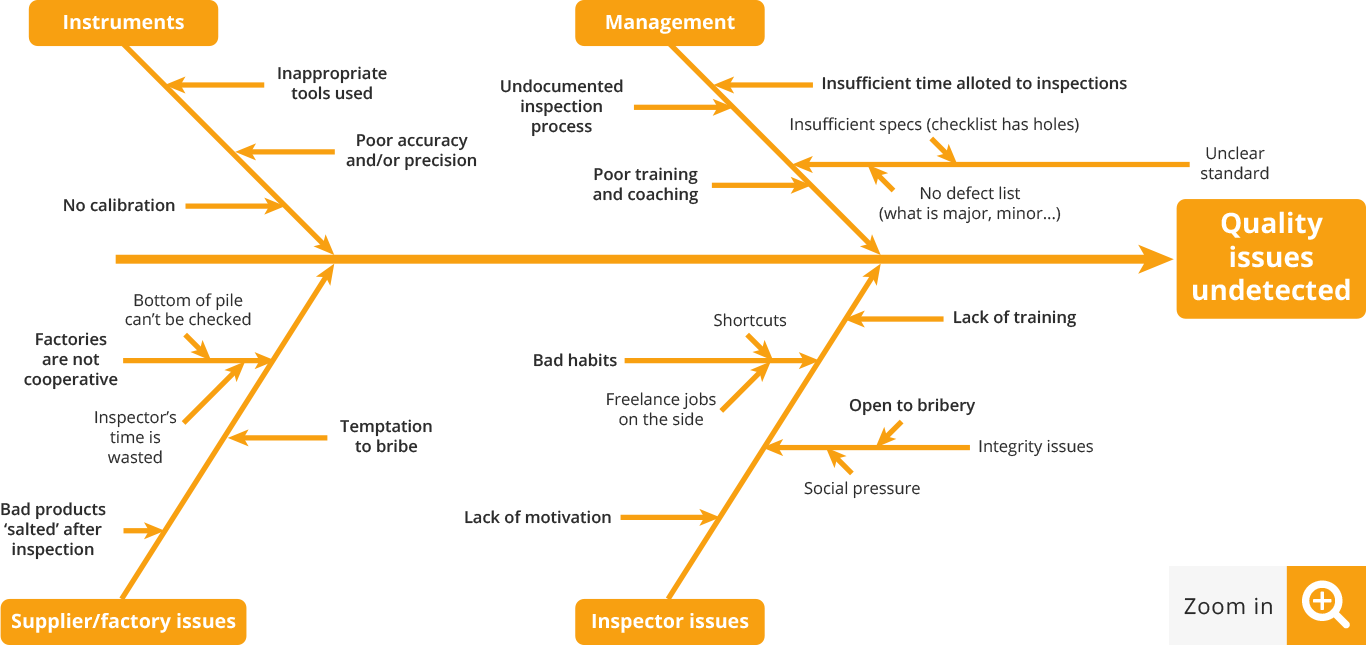

One of the most common causes of an inspection that fails to identify issues is that the inspector responsible hasn’t received adequate training. We’ve found that many buying offices expect their new hires to learn on the job from more experienced colleagues, rather than giving them the required training to understand both inspection processes and product-specific issues.

Poor training inevitably leads to them making mistakes.

Another reason why standardized training is so crucial is that newly-hired inspectors can arrive at your buying office with plenty of skills but also bad habits they have picked up from wherever they were before. If these are allowed to spread like a virus across your other staff, it can cause real problems.

Bad habits can include not doing the full required number of checks, picking the most convenient samples or just rushing the job through.

In any business, you need your staff to be motivated, and it’s essential for quality inspectors due to the nature of their work. If they aren’t taking pride in their work and aren’t sufficiently positively motivated, they will not do a thorough job. That’s human nature, and it is something you need to avoid setting in. Finding ways to motivate your inspectors will ensure that defective products are picked up.

A significant point of contention during and after inspections is what constitutes a defective product. For some products and some issues, it can be clear-cut, but if there is no defined standard for what is and isn’t a defect, it can come down to a battle of wills between the inspector and the supplier when it comes to classifying whether an issue is major enough to report. Inspectors need to go armed with a visual checklist at the very least to back up and confirm their findings and avoid dispute.

Like anyone in their position, quality inspectors need the right tools to help them do the job correctly. Inspectors using the wrong tools will not be able to carry out their inspections successfully, so a checklist must be maintained to ensure consistency in the quality of the tools provided and the way they are calibrated.

Many of the issues we’ve identified above come about because of the way quality inspection processes are traditionally undertaken. Sticking with an ‘if it ain’t broke, don’t fix it’ approach only works if it truly isn’t broken, and the traditional quality inspection process does seem to be very broken.

Switching to using quality inspection software can address so many of these problems, let’s see some examples:

The process of setting up inspection dates can be long and confusing when done over emails, with attachments flying back and forth and no consistency or cohesion. This leads to uncertainty and mix-ups that can waste time and cause knock-on issues, and it can be so easily avoided by utilising quality inspection software at both ends of the process. This allows for simple coordination and confirmation and no confusion.

Similarly, if the date keeps changing and it is hard to keep track of inspections, it is almost impossible to assign inspectors with any degree of confidence. This means that appointments get switched, inspectors get assigned to factories outside of their expertise, and the system is inefficient, to say the least.

Aside from the problems that can come from actually assigning inspectors, getting them the information they need to complete their inspection can be a whole other issue without the right software. With the software, you can ensure that the right file gets to the right person and is available whenever they need it.

It can take a long time for staff to write and send their report after inspections, occasionally over an hour, and this is wasted time that can be spent more productively. Using quality inspection software means the report is created as part of the inspection process and is ready to be sent as soon as it is completed.

Without consistency in the way, reports are filed, and communications are made, it can be very difficult to follow up on serious issues that arise as part of inspections. Issues can be forgotten about, whether accidentally or otherwise, and chasing up suppliers can be time-consuming and frustrating. With the right software, the issues remain on action plans until they are resolved, and there can be no mix-ups.

We’ve just highlighted some ways that quality inspection software can help your inspections run more smoothly, but there are plenty more positives as using it can save you both time and money. When it comes to managing the way your inspections are carried out and reported, who can say they don’t need to make savings in both of these areas, without compromising on the quality?

Here are some examples of how:

Nothing adds to your time and costs like unnecessary mistakes, especially when it comes to quality inspections. If a bad batch of products slips through, it can be damaging to reputations all around, costing repeat and future business. Using quality inspection software ensures that the work is carried out in a structured manner, minimizing the chances of mistakes being made.

Another benefit of having the statistics package as part of the software is that it enables you to spot issues that keep on happening at factories. These recurring issues are obviously not being resolved by the suppliers and may not even be getting identified by the inspectors, but can be demonstrated and resolved thanks to the quality inspection software.

It’s often the case in Chinese quality inspections that the inspectors are chosen for their ability to fill out the forms in English rather than their product knowledge. This also means that those inspectors who have good knowledge AND good English can command very high salaries. Utilising quality inspection software means that the language skills are far less essential as the inspection requires box-ticking and photography much more than writing anything down in an unfamiliar language.

As mentioned above, inspectors can do their work on either a mobile phone or a tablet with the quality inspection software app installed, which saves them from having to carry a bulky laptop computer around with them or conducting the inspection on paper and transferring the information over later. These handsets don’t need to be top of the range Apple either, merely reliable and affordable products.

Not only does the new reporting system save time for the inspectors, but it also enables the buying office and the suppliers to see everything from the inspection as soon as the handset is able to transmit it via wifi or cellular data. This means that everything can start to be actioned immediately and decisions can be made much more quickly.

If the last section has inspired you to find ways to make real savings in costs and times on your quality inspections, there are other ways to do this alongside switching to the right software.

Here are some suggestions based on our experiences:

Instead of using a calliper over and over to check the dimensions of a product, supply your inspectors with a custom measurement gauge that can save them time and energy and improve the efficiency of your inspections.

We’ve spoken of the problems caused by inspectors taking shortcuts, but not all shortcuts are necessarily bad. Identifying where time can be saved without cutting corners or risking defective products getting through can be beneficial to all concerned. A good example would be stacking together products that are meant to be identical so any variations in size and color can be easily identified in much quicker time than inspecting them separately.

Some products can have hundreds of checkpoints that can be reviewed in an inspection, but going through all of them can take a lot of unnecessary time. Identify where the checkpoints are that relate to what customers value as important and where time can be saved on skipping those that are easily recognizable as being faulty through general use of the product.

Quality inspection software can help identify recurring problems with products, and this can aid investigations into why these happen. Sometimes, time can be saved, and defects can be avoided by simply checking the machinery that does the manufacturing and finding ways to ensure that the glitches are repaired. If this fixes the recurring problems, time can be saved on checking for those in the future.

So far we have covered the general benefits of using quality inspection software, but each industry has its own requirements and specific issues. To help you understand how software can benefit you, here’s an industry-by-industry breakdown:

Buying promotional products from China comes with specific challenges, whether you are sourcing samples or purchasing regular products for catalogues. Using quality inspection software when you are producing promotional products helps speed up the sourcing process, enables you to chase up regular suppliers when issues arise and improve the efficiency of inspections where high quality is required.

Another factor is the loading of products onto a container, which can lead to problems if not done correctly and this is where furniture importers using quality inspection software with real-time findings particularly benefit as the buying office can immediately see photos of what is happening during loading.

These products can come in all shapes and sizes and with multiple SKUs and factory sources, so keeping track of all of them in a traditional inspection process is almost impossible. This is where the right quality inspection software can make all the difference to home and decoration product manufacturers, as everything can be inputted into it and tracked accordingly. This saves time, effort and avoids a lot of confusion and the potential for important details to be missed

Again, these can vary widely regarding size and complexity and also come with a much higher risk of serious problems occurring if defects are missed in the quality inspection. Checking a toaster and an oven are very different processes, so it helps to have quality inspection software suited to electrical home appliance manufacturers available that provides the individual checklists required to ensure that each specific detail is included.

The potential severity of problems makes it all the more important that recurring problems are identified through the software and tracked until resolved at the factory; which is something often missed in the traditional inspection process.

For inspections of mechanical products, it is particularly crucial to have access to a lot of detail about the products and the parts that go into them, and this can be difficult to access if not using specialized quality inspection software for mechanical product producers, which provides them to you in the palm of your hand. Keeping all the data from past inspections and have that available too is another major advantage in this area.

We’ve found the garments industry to be particularly reliant on traditional inspection methods and tools, as opposed to the electronics industry for example. This can perhaps be due to a lack of familiarity with tools like software, but the benefits to garment manufacturers of quality inspection software are clear as things like size charts can be rendered so much more easily than when done in a programme like Excel. A software solution that also speeds up the process of inputting measurements will save a lot of time and improve consistency and accuracy of reporting.

I will assume you pay for it under a SAAS (Software As A Service) license.

Compare that to the fully loaded cost of each inspector – including salary, 13th-month bonus, social insurance, travel expenses, hardware (laptop, camera, etc.) management time, and so on. It often amounts to more than 1,500 USD a month. So the cost of equipping them with dedicated software and save them time (1 hour a day in reporting, etc.) is 5% of their total cost.

It usually makes sense to follow this sequence:

The companies that will benefit the most from quality inspection software are those that:

Note – if you need your QC team to check many products in 1 day, or to go to 2-3 factories in 1 day, make sure you choose a software solution that supports this workflow. (With SynControl it is no problem.)

Here are telltale signs that you should make the switch soon: