SynControl empowers your product quality & compliance team to work efficiently

Secure Archival of Technical Folders

Auto-Request Files from Suppliers

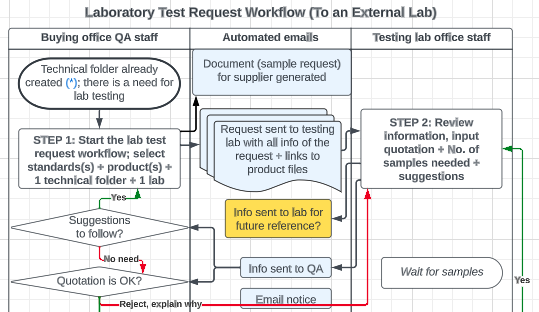

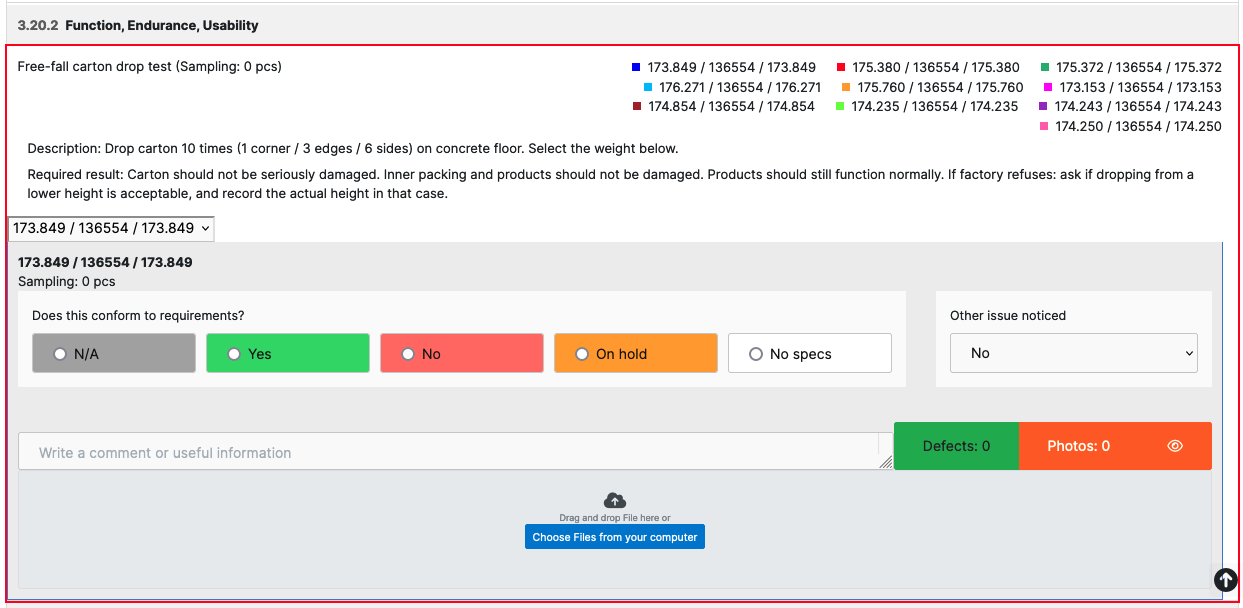

Auto-Request Lab Test from Labs

Auto-Initiate Supplier Self-Inspection

Auto-Generate Compliance Documents

Intuitive Status Dashboards

Possible ERP and PLM Integrations

And many more features!